SHENLONG New Material Industrial Park

SLXCL New material project, has been built with independent intellectual property rights of metal laminated composite new material industrial park. This project has the core technology and patent of the enterprise, independently developed and produced metal lamellar composite material, which is a ne

Read More

Copper-Clad Steel: Optimizing Waterstop Solutions

Copper-clad steel emerges as an economical alternative to traditional copper waterstops, offering 60-70% material cost savings while maintaining essential corrosion resistance. SLXCL's innovative composite combines 6-8% brass cladding with 90+% steel core, delivering reliable performance for infrastructure projects.

Read More

Invitation to IDEF 2025

Join us at Booth 11-G06 during IDEF 2025 (22-27 July, Istanbul Expo Center) to explore our premium Customizable Bullet Case Cups made from CuZn10 Clad Steel (F11/F18). Discover defense industry innovations in Turkey.

Read More

Performance Advantages of T2+IF+T2 Copper-Clad Steel Composite Waterstop

The T2+IF+T2 copper-clad steel composite waterstop achieves unparalleled waterproofing performance through its corrosion-resistant copper layer and high-strength steel core, creating the ultimate protective barrier for modern construction.

Read More

Application of Copper-Steel Composite Material in Military Bullet Casings: Low Cost, High Performance

Copper-steel composite material, with its cost-effective advantage and maintained performance in bullet casings, is revolutionizing ammunition manufacturing and expanding into military fields, addressing cost and resource concerns.

Read More

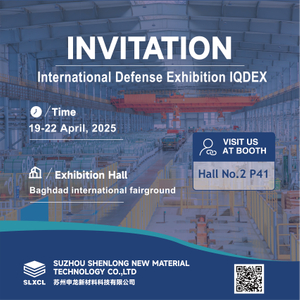

【Invitation】SLXCL Invites You To IQDEX 2025

Visit SLXCL at IQDEX 2025 and discover how our composites can transform your supply chain!

Read More

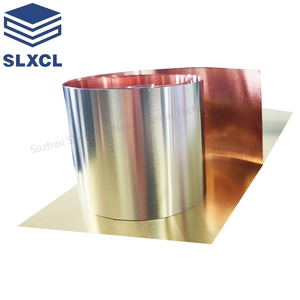

Precise Cold-rolled Composite : The First Step in High-Performance Copper-Clad Steel Production

Let's take a closer look at the first and most critical step in our production process – the laminating process – and how it operates with precision to meet customers' requirements for tolerances and performance.

Read More

The Past And Present of Shen Long

The Past of ShenLongWujiang Escalator Factory was established in 1992 under the name of Xinta Town Agricultural Company. In 1996, it was transformed from a collective enterprise into a private-owned entity and renamed "Suzhou Shenlong Elevator Co., Ltd." In 2012. Suzhou Shenlong Heavy Industry Machinery Co., Ltd. was established in 2009 when Shenlong Elevator invested 200 million RMB to found "Suzhou Shenlong Heavy Industry Machinery Co., Ltd." In 2018, it was renamed "Suzhou Shenlong New Materials Technology Co., Ltd." and specialized in researching and developing various functional new materials, such as copper + steel + copper and copper + stainless steel + copper composites.

Read More

SLXCL Invites You to Visit HuntEx 2025 in South Africa

Join us at Booth HALL5 525C during HuntEx 2025 to experience how SLXCL’s copper-clad steel composites deliver innovative, efficient solutions for defense applications.

Read More

Copper-Clad Steel Manufacturing Process: Precision & Quality Control

Let's explore the production process of copper-clad steel together!

Read More

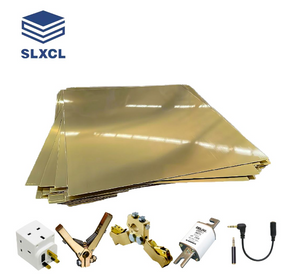

Four Key Applications of SLXCL's Copper-Clad Steel Materials

Let's learn more about the four main application areas of our copper-clad steel materials—military, electronics, electrical appliances, and copper tubes—and discover how they excel.

Read More

Innovative Applications of T2+IF+T2 Composite Material: From Military Detonators to Civilian Fields

The T2+IF+T2 copper-clad steel composite material combines the corrosion resistance of copper and the high strength of steel through its three-layer composite structure.

Read More

Join SLXCL at MILIPOL 2025 Exhibition in Paris

Welcome to visit our booth at Hall4-A3 in MILIPOL 2025 Paris

Read More

SLXCL’s Custom Copper-Clad Steel Solutions: Navigate Volatile Copper Prices

Amid high and volatile copper prices, SLXCL’s custom copper-clad steel (single/double-sided cladding) offers cost stability and tailored performance.

Read More

Join SLXCL at The Tri-Service Asian Defense & Security Exhibition in Thailand

SLXCL will showcase high-performance brass clad steel case cup and specialized Cuzn10+F11/F18+Cuzn10 triple-layered composite metal strips for military applications at the D&S Thailand (11-13 November, MPACT, Thailand). Visit us at Booth N40-2 to explore advanced solutions and discuss collaborations.

Read More

Revolutionizing Smartphone Cooling with Ultra-Thin T2+304 Copper-Clad Steel

Discover how T2+304 copper-clad steel, with its remarkable thinness of 0.06mm, transforms heat dissipation in smartphone chipsets.

Read More

Cold-Rolled Metal Composites: Strong Bonding Technology Breaking Performance Limits of Single Metals

Shenlong New Materials achieves strong interfacial bonding through cold-rolling composite technology, breaking performance limits of single metals to deliver more reliable substrate solutions for industrial applications.

Read More

Invitation to ARMY 2025 – Visit Our Booth 4C6-12 for Custom Bullet Case Cups

SLXCL cordially invites defense industry partners to ARMY 2025 in Moscow (August 11-14, Booth 4C6-12) to discuss potential cooperation opportunities.

Read More

Broad Application Prospects of T2+IF+T2 Composite Waterstop

From bridges to renewable energy projects, the customizable T2+IF+T2 composite waterstop delivers adaptive solutions for tomorrow's waterproofing challenges across all engineering sectors.

Read More

Customizable Bullet Case Cup Solutions with Brass Clad Steel Material

Traditional pure brass cartridge cases cup face two critical pain points: high costs and insufficient strength. SLXCL innovative CuZn10+F11/F18+CuZn10 tri-layer composite structure breaks through these limitations through material science advancements. Let's examine how this breakthrough works.

Read More

English

English