Tel: +86-512-88983889-8066 E-mail:service@slxcl.com.cn

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 92 Author: Site Editor Publish Time: 2025-07-16 Origin: Site

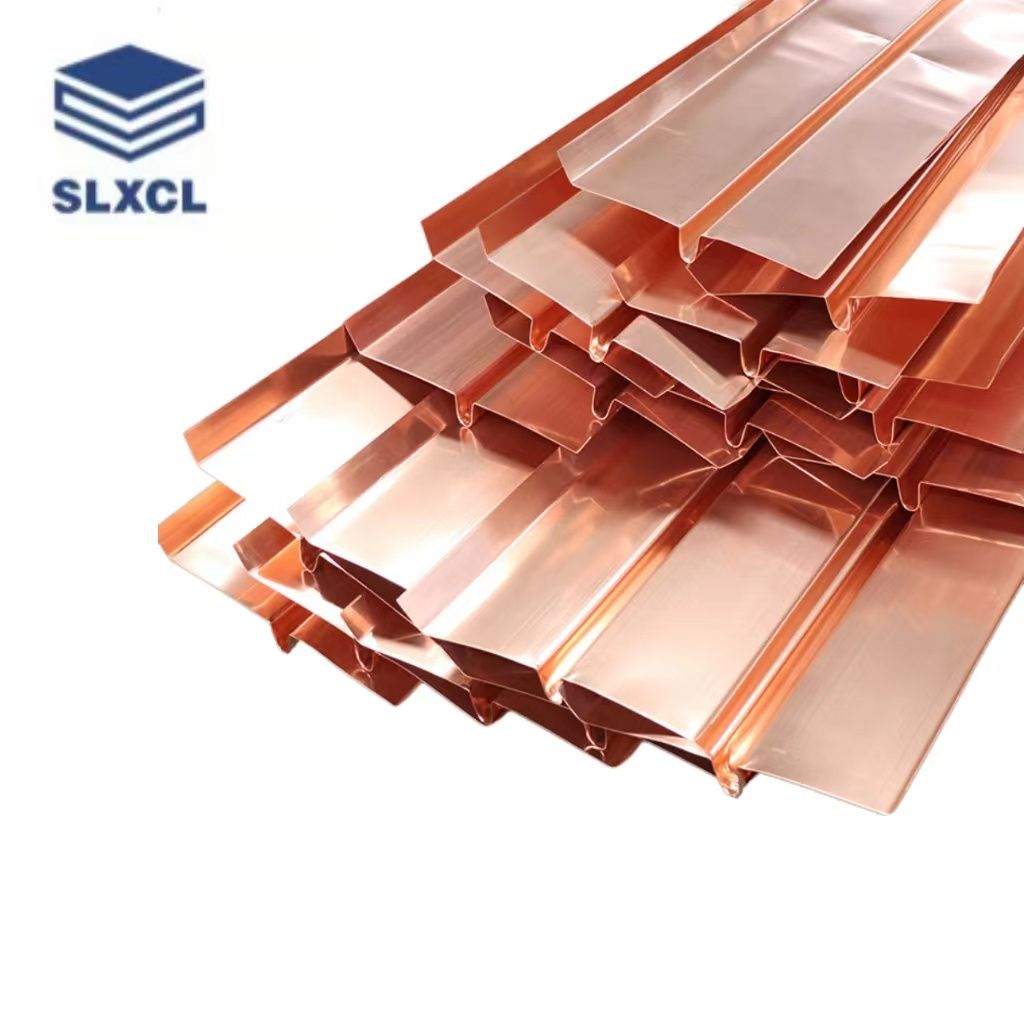

Copper waterstops have been widely used in construction joints for their excellent corrosion resistance. However, pure copper has notable limitations, including high material costs (typically 2-3 times more expensive than steel), limited mechanical strength, and a single-performance profile that restricts its application flexibility.

SLXCL's brass-clad steel provides an innovative solution to these challenges through advanced material engineering. The composite structure features a 6-8% brass outer layer, which delivers corrosion protection comparable to pure copper in most environments, while the 90+% steel core significantly enhances tensile strength—up to three times that of traditional copper waterstops.

In addition to its technical advantages, brass-clad steel offers substantial cost savings, reducing material expenses by approximately 65% compared to pure copper. Its compatibility with standard welding and joining techniques ensures seamless integration into existing construction processes without requiring specialized installation methods.

This material is particularly well-suited for critical infrastructure applications, including tunnel construction joints, dam expansion joints, and underground parking waterproofing systems. By combining cost efficiency with reliable performance, SLXCL's brass-clad steel presents a balanced alternative that maintains essential water barrier functionality while optimizing project budgets.

For project planners, SLXCL's brass-clad steel offers a balanced solution that cuts costs without compromising critical water barrier functions.