2025-10-29 Welcome to visit our booth at Hall4-A3 in MILIPOL 2025 Paris

Read More

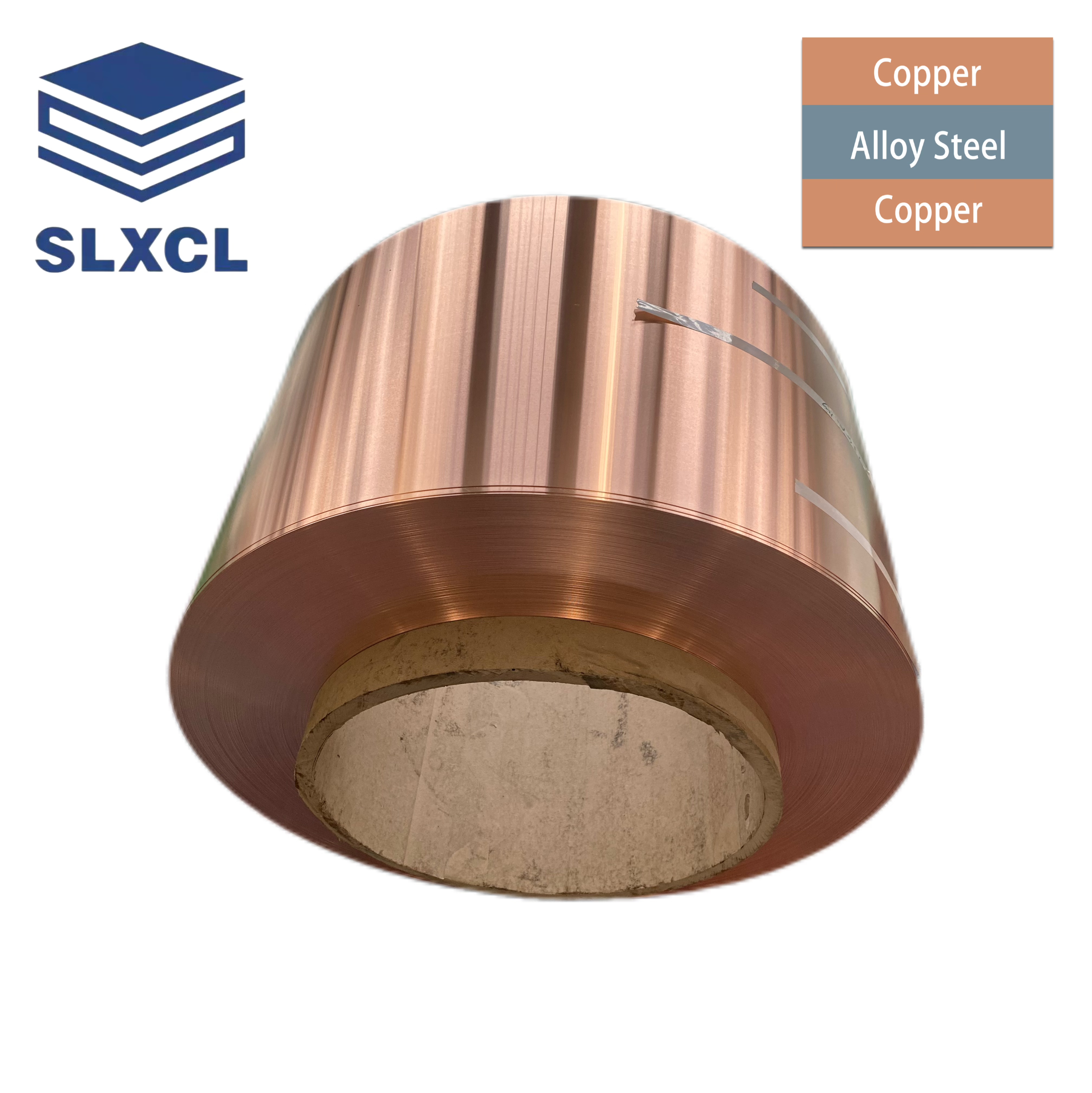

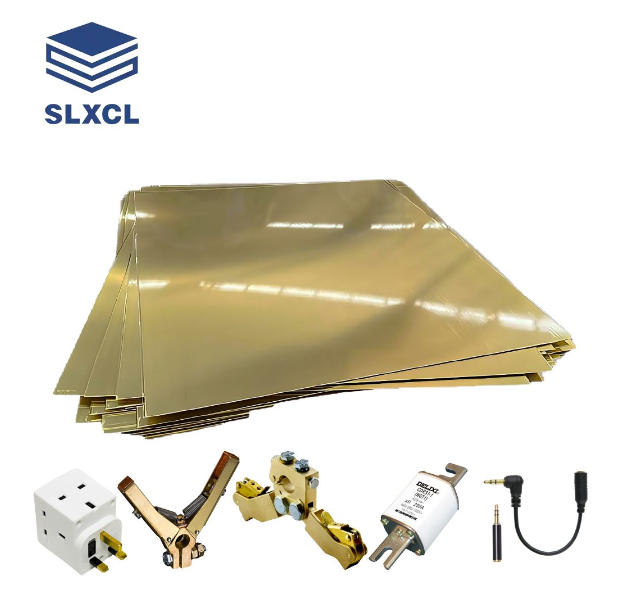

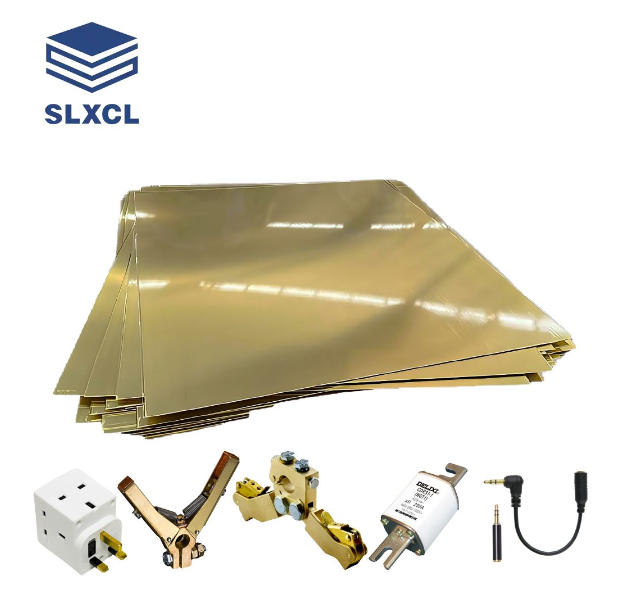

2025-09-23 Let's learn more about the four main application areas of our copper-clad steel materials—military, electronics, electrical appliances, and copper tubes—and discover how they excel.

Read More

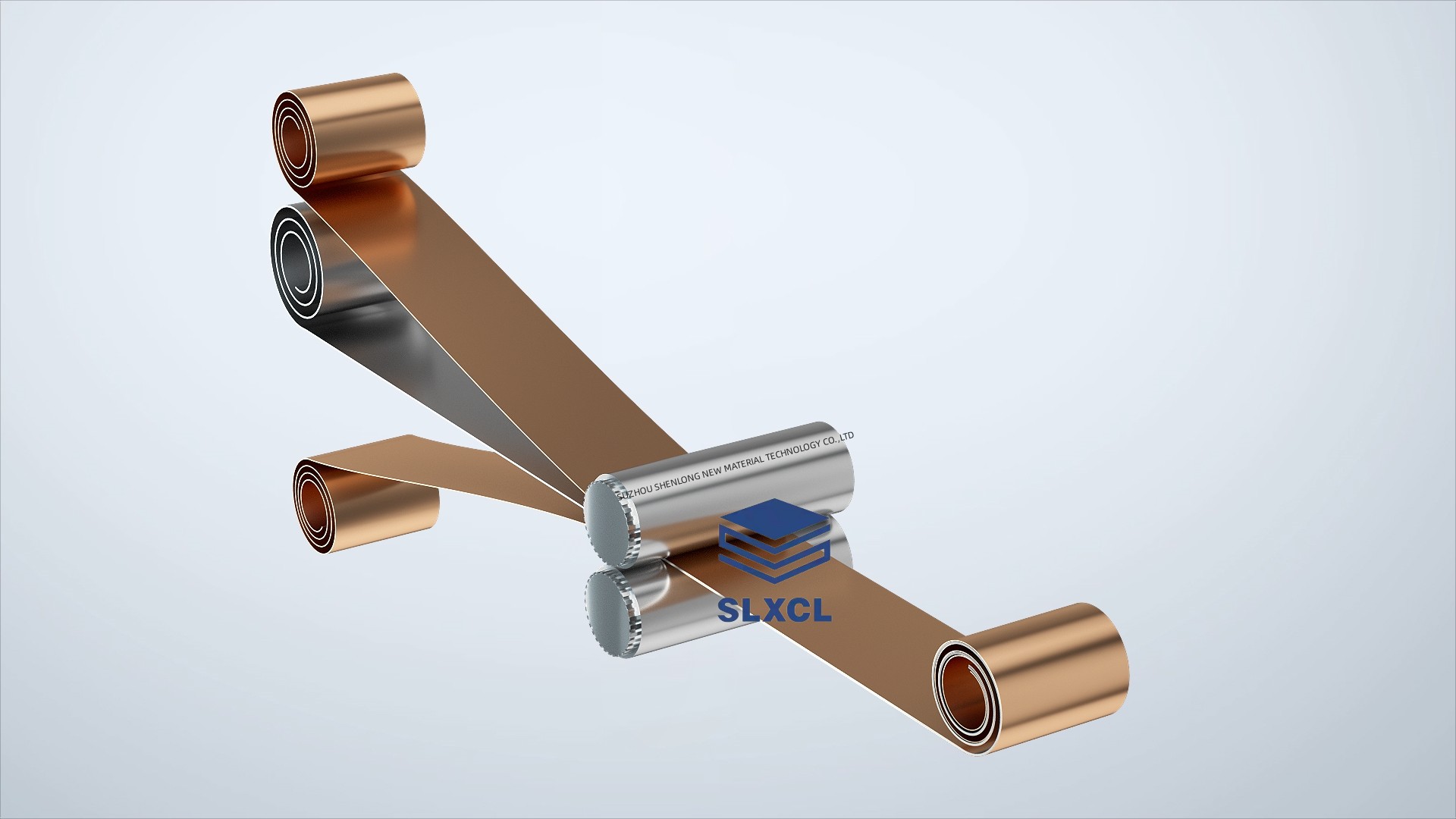

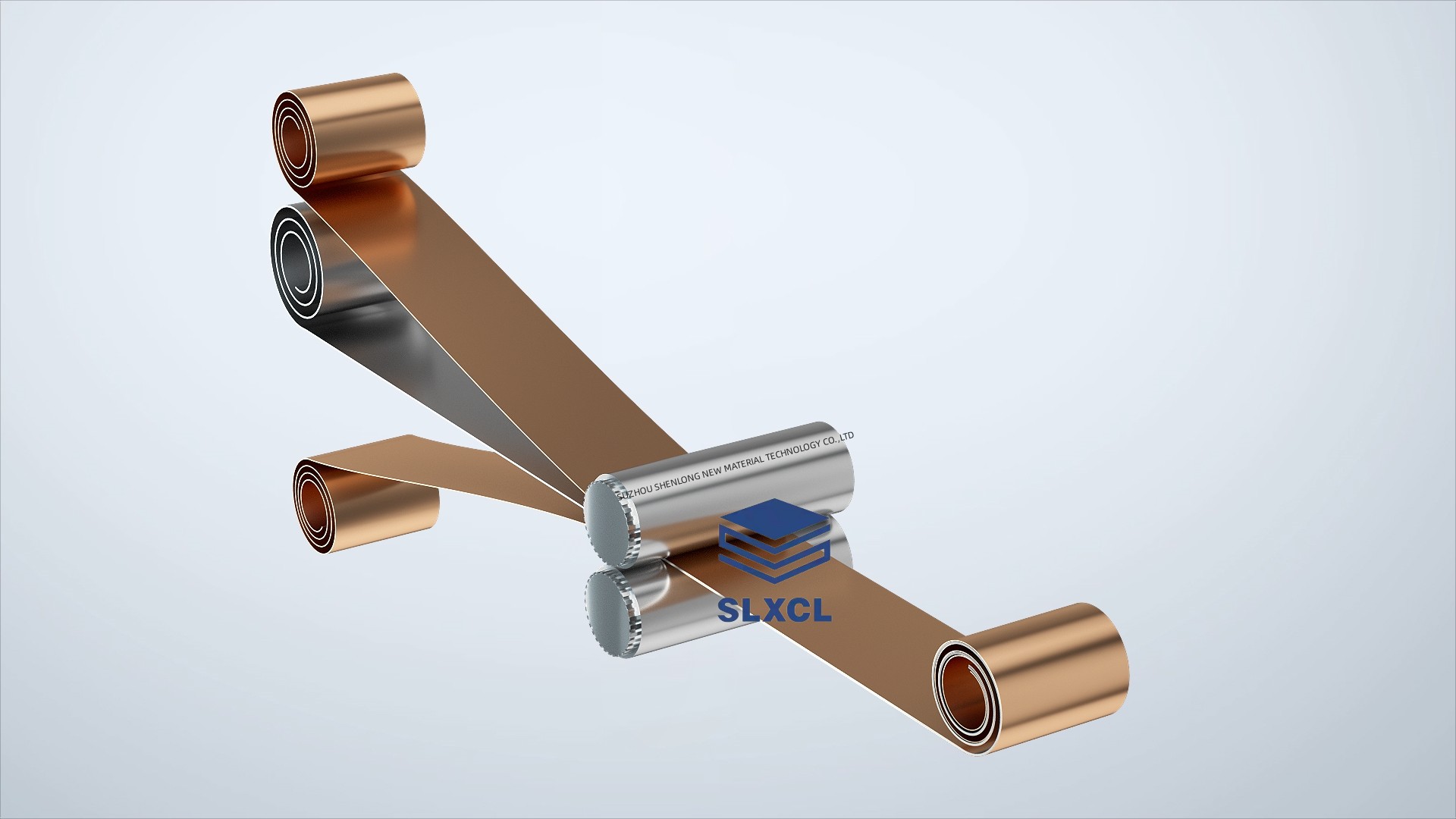

2025-08-12 Shenlong New Materials achieves strong interfacial bonding through cold-rolling composite technology, breaking performance limits of single metals to deliver more reliable substrate solutions for industrial applications.

Read More

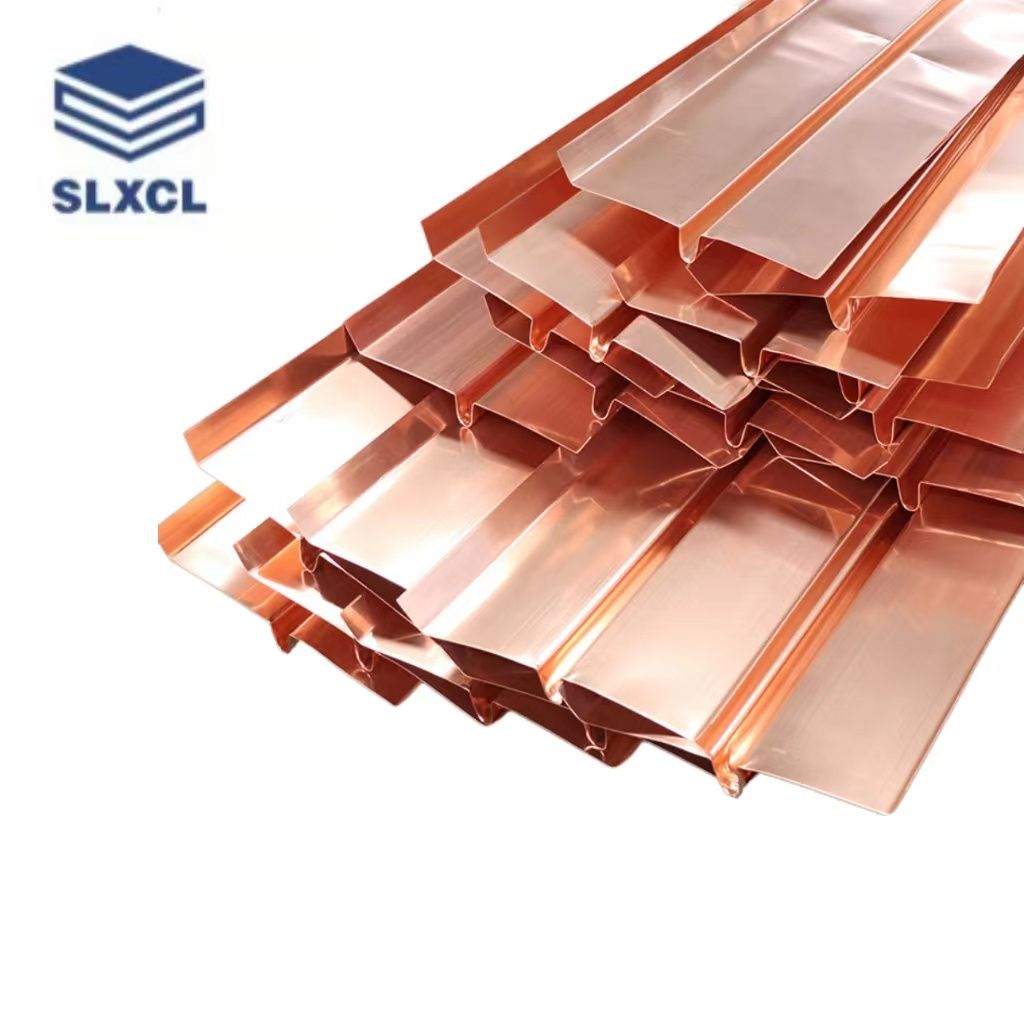

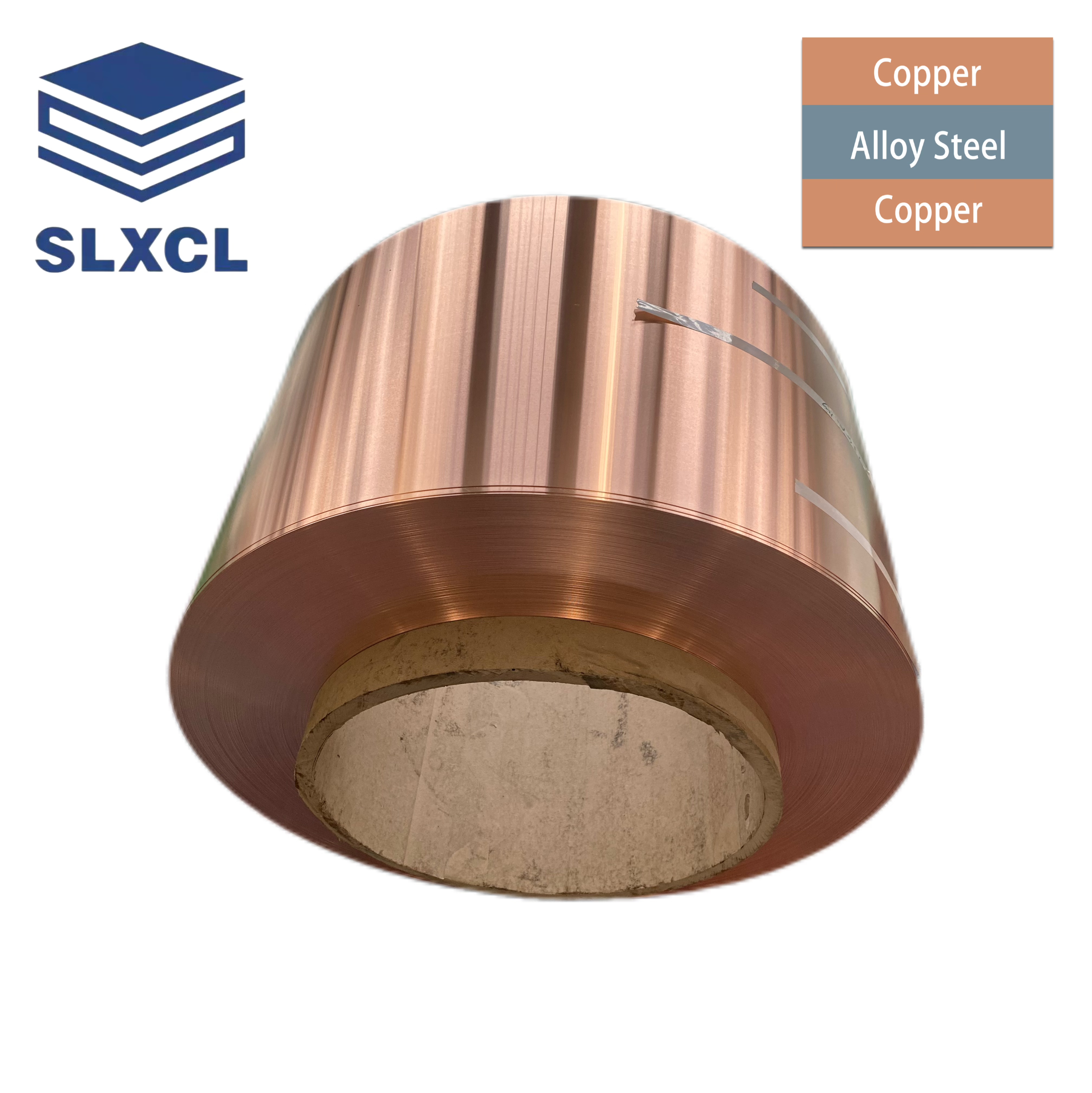

2025-07-16 Copper-clad steel emerges as an economical alternative to traditional copper waterstops, offering 60-70% material cost savings while maintaining essential corrosion resistance. SLXCL's innovative composite combines 6-8% brass cladding with 90+% steel core, delivering reliable performance for infrastructure projects.

Read More

2025-07-08 SLXCL cordially invites defense industry partners to ARMY 2025 in Moscow (August 11-14, Booth 4C6-12) to discuss potential cooperation opportunities.

Read More

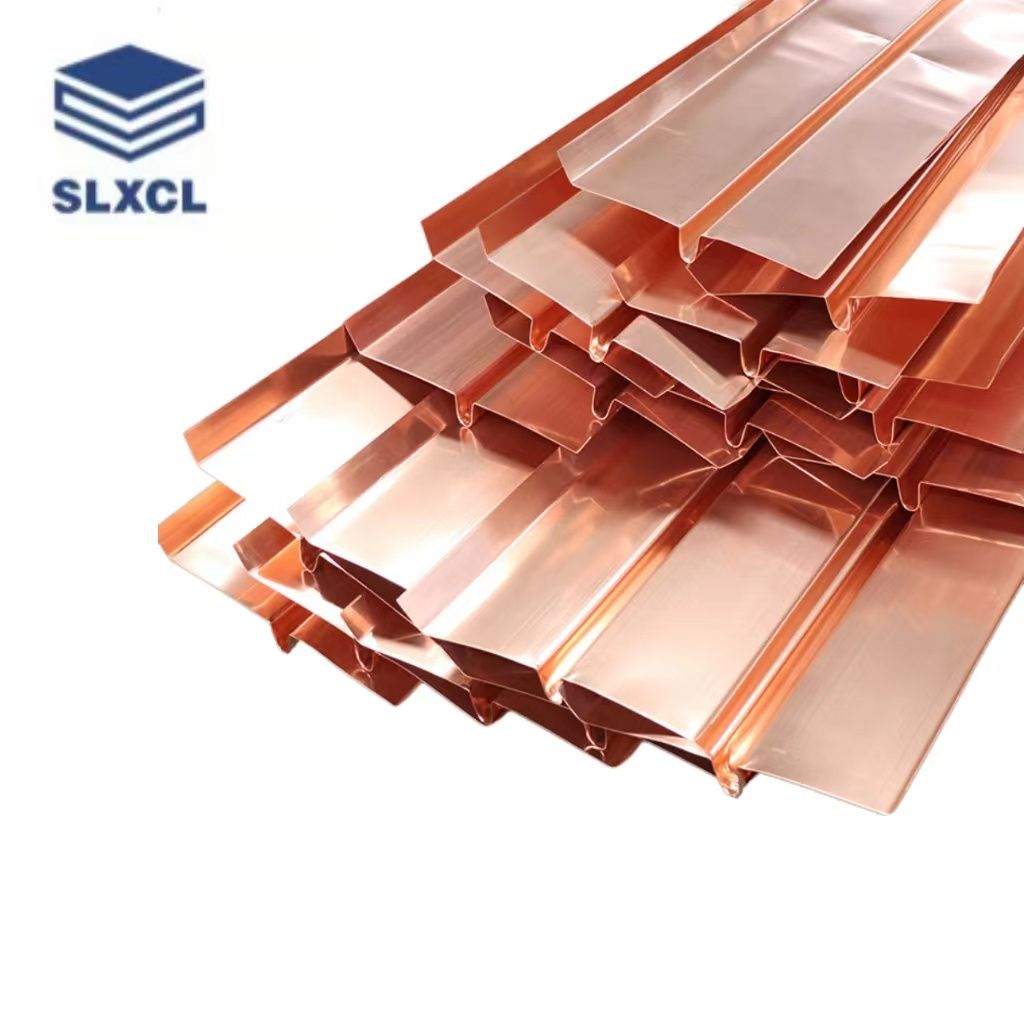

2025-06-19 From bridges to renewable energy projects, the customizable T2+IF+T2 composite waterstop delivers adaptive solutions for tomorrow's waterproofing challenges across all engineering sectors.

Read More

2025-05-27 The T2+IF+T2 copper-clad steel composite waterstop achieves unparalleled waterproofing performance through its corrosion-resistant copper layer and high-strength steel core, creating the ultimate protective barrier for modern construction.

Read More

2025-05-06 The T2+IF+T2 copper-clad steel composite material combines the corrosion resistance of copper and the high strength of steel through its three-layer composite structure.

Read More

2025-04-21 Let's explore the production process of copper-clad steel together!

Read More

2025-04-17 Join us at Booth HALL5 525C during HuntEx 2025 to experience how SLXCL’s copper-clad steel composites deliver innovative, efficient solutions for defense applications.

Read More