Tel: +86-512-88983889-8066 E-mail:service@slxcl.com.cn

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 329 Author: Site Editor Publish Time: 2025-04-21 Origin: Site

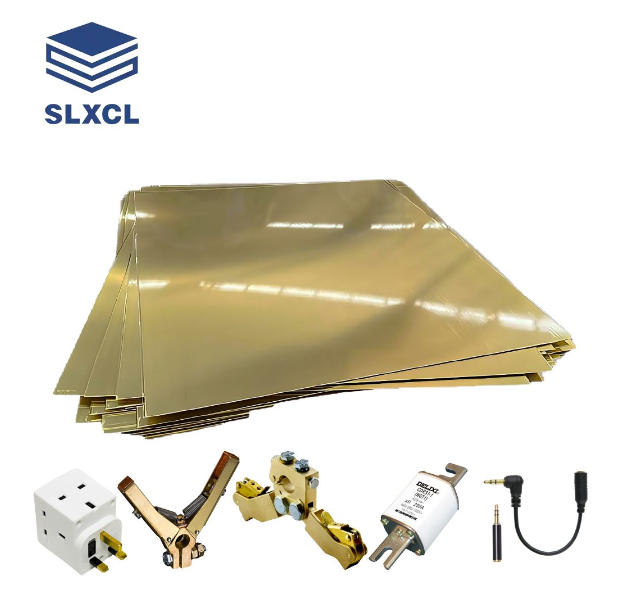

Copper-clad steel is a high-performance composite material widely used in electrical, automotive, and construction industries. Its production involves multiple critical stages to ensure durability, conductivity, and corrosion resistance.

After rigorous raw material inspection, the base steel and copper overlay are laminated into double-layer or triple-layer composite plates, customized to meet specific customer requirements.

This heat-treatment process adjusts the material’s hardness and elongation, ensuring optimal physical properties for industrial applications.

A high-tolerance rolling process refines the material to meet strict thickness and surface quality standards, enhancing performance in precision engineering.

Chemical treatments remove surface residues, restore natural copper color, and apply passivation to improve corrosion resistance.

This step eliminates the yield plateau effect, restoring flatness and mechanical properties for consistent performance.

Final cutting ensures the material meets exact customer-specified widths, ready for industrial use.